Vertical Turning Lathes

Vertical Turning Machines (VTL) otherwise called Vertical Turning Communities, have seen nonstop advancements since its origin. New renditions of Vertical Turning Machines integrate numerous useful advances and these days are a lot more grounded, flexible and with further developed unbending nature. Huge castings and vast way frameworks guarantee precise and stable machining on all of our upward turning machines. Rock solid transmissions, which are standard on bigger models, permit stock expulsion at high axle speeds.

VTL Series vertical turning lathes:

- We work in exceptionally enormous machines with table distances across up to 4 meters and max swing measurements up to 4.5 meters!

- Slicing levels up to 2.5 meters!

- Have an exceptionally weighty work piece? We have hurls that can deal with up to 80,000 kg (88 us ton)!

- We offer both Turret and Smash style machines!

- Need full C-Pivot with live tooling? We can make it happen! With up to a 50 HP live tooling!

- Our high thickness castings are heavier with less webbing. This implies less sounds and less warm variety!

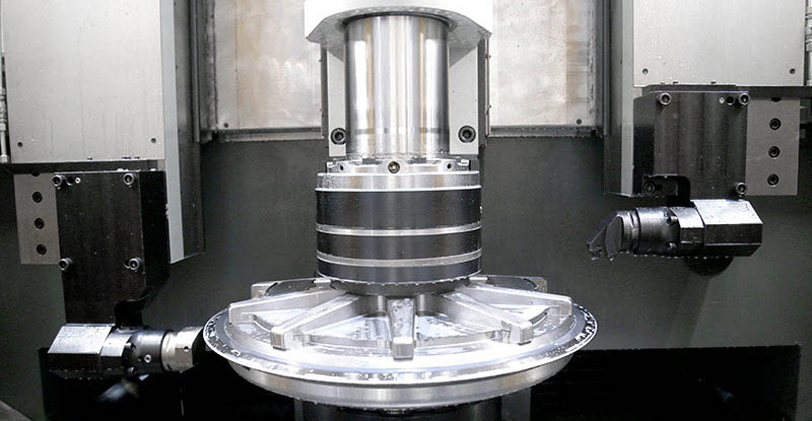

Vertical Lathe Components

- Chuck sits toward the finish of the shaft and holds the workpiece as it pivots

- Jaws safely holds the workpiece in the hurl

- Ways z-axis drives the chopping apparatuses all over to perform cutting cycles

- Ways x-axis The rail that moved the workpiece in and out, situating the shaper closer or farther away from the middle.

- Workpiece - the piece being machined that clips into the jaws of the throw

- Multi-device turret - holds various cutting apparatuses for various tasks and changes them out consequently

- Bed - the heavy cast iron base underneath the work area that the chuck is attached to.

The Advantage of Vertical Turning

There are sure applications where an upward turning machine enjoys an upper hand over other machining arrangements. We exploit this to deliver better parts and more effective machine pieces.

Weighty workpieces are effortlessly set up and held set up while machining. Gravity works with the machine to keep the part set up, and insignificant clasping is required contrasted with different cycles. Our machines can achieve this while occupying less room than a similar flat machine would. Our upward machines oblige greater and heavier castings inside our shop than a level machine would. We can take heavier cuts securely without wrecking our resiliences. This eliminates process durations since we can all the more forcefully eliminate material. We have some control over the last surface completion from semi-completed to fine, giving our clients fantastic outcomes right off the machine with no crushing required.